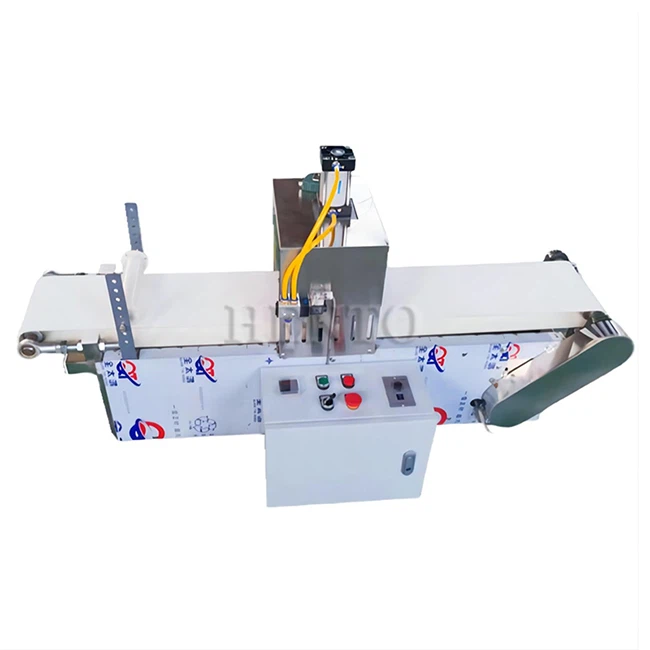

Vermicelli Cutting Machine

Vermicelli Cutting Machine helps in cutting and shaping the pasta into long, thin, and uniform shapes.

Application

The Vermicelli Cutting Machine is highly versatile and can be applied in various settings, including homes, eateries, restaurants, and industrial pasta production plants. The application of the machine is critical in achieving uniformity in pasta products, which is important for the pasta industry. The machine is capable of cutting and shaping noodles or spaghetti strands of equal lengths and thickness. It can be operated manually, electrically, or pneumatically, depending on the device's size and capacity. Small units are commonly used in households, while larger machines are used in mass production.

Advantages

It comes with many advantages that make it an essential kitchen gadget. Here are some of the benefits of the machine:

1. Time-saving - The machine helps to save time in the pasta production process. The time it takes to cut and shape noodles or spaghetti strands manually is significantly reduced. This is beneficial for the pasta industry as it increases productivity and helps meet the growing demand for pasta products.

2. Uniformity - The machine guarantees uniformity in the length, thickness, and shape of the pasta. This is essential in pasta production, as it helps to achieve a consistent texture and taste in the final product.

3. Cost-effective - The machine is cost-effective as it reduces the need for manual labor in the production process. This helps to save on wages and overhead costs, making the pasta business profitable.

4. Easy to operate - The machine is easy to operate and can be used by anyone with minimal training. This is beneficial for both home and industrial users of the machine.

5. Hygienic - The machine's stainless steel construction makes it hygienic and easy to clean, reducing the risk of contamination in the pasta production process.

Working Principle

The machine operates based on a simple principle. The machine consists of a roller system that flattens the pasta dough sheet. The flat sheet is passed through a cutting unit consisting of rotating knives, which cut the pasta into strands of equal length and thickness. The machine can cut the pasta into various shapes, including vermicelli, spaghetti, tagliatelle, and fettuccine. The cutting unit's size and shape vary according to the pasta shape required.

How to Operate

The machine is easy to operate, and the following steps are usually followed:

1. Preparation of Pasta Dough - Start by preparing the pasta dough according to the desired recipe.

2. Adjust the rollers - Adjust the rollers according to the desired thickness of the sheet. This is usually done by turning a knob to adjust the roller distance.

3. Pass the dough through the rollers - Pass the pasta dough through the rollers several times to achieve the desired thickness.

4. Adjust the cutting unit - Adjust the cutting unit to the desired shape and size of the pasta.

5. Cut the pasta - Pass the pasta dough sheet through the cutting unit to cut the pasta into strands of equal length and thickness.

6. Collect the pasta - Collect the cut pasta in a tray or container.

Product parameters

|

Product Name |

Pasta Cutting Machine |

Pasta Cutting Machine |

|

Model |

HT-QD100 |

HT-QD200 |

|

Capacity |

200-300kg/h |

400-500kg/h |

|

Power |

160W |

1500w |

|

Voltage |

220V |

220V |

|

Dimension |

2000*500*700mm |

2050*780*1240mm |

|

Weight |

68kg |

128kg |

|

Reference Price |

USD779.01 |

USD1137.37 |

Hot Tags: vermicelli cutting machine, China vermicelli cutting machine manufacturers, suppliers, factory, Commercial Dough Divider Rounder Machine, Walnut Cookie Machine, Hard and Soft Biscuit Production Line, Automatic Animal Feed Production Line, Instant Noodle Production Line, Baguette Bread Dough Moulder

You Might Also Like

Send Inquiry